Project Description

Several of ProSensus’ recent custom machine vision installations in the foods industry have included both color and thermal cameras.

The digital images obtained from this combination of cameras provide numerous measurements that can be used to accomplish a variety of goals.

Machine Vision Goals

Some examples of vision system goals include:

Some examples of vision system goals include:

Real-Time Measurement of Key Parameters

Automate real-time measurement of key quality parameters such as product temperature, product size and product color. In comparison to manual measurements, automated quality measurements provide higher resolution data while reducing lab time, and this data may be valuable to quality improvement initiatives.

Model and Predict Advanced Properties

Model and predict advanced properties such as product texture. ProSensus applies advanced analytics to the images to extract features that can then be correlated to the key product properties. The machine vision system is then used as a soft-sensor to predict quality metrics that may otherwise be lengthy and expensive to obtain (such as through advanced lab analysis or consumer testing).

Adjust Process Conditions

Adjust process conditions such as oven or freezer temperature, conveyor speed, etc. The outputs of the machine vision system are provided to the client’s PLC to facilitate appropriate adjustments to the process conditions in order to reduce quality variability.

Ensure Safety Standards are Achieved

Ensure food safety standards are achieved and maintained such as those required for pasteurization and frozen food storage. The machine vision system provides automated, real-time measurements that are used for monitoring and alarming food safety criteria.

Custom HMI Displays

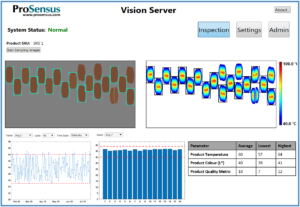

Each machine vision system designed by ProSensus includes a custom HMI display. Typically, the HMI display includes live images from both cameras, as well as graphical tracking and tabular summaries of quality attributes of interest.

Turnkey Solutions

A turnkey machine vision solution from ProSensus typically includes: design, software, hardware, factory acceptance test, and post-comissioning support.

A turnkey machine vision solution from ProSensus typically includes: design, software, hardware, factory acceptance test, and post-comissioning support.

The following hardware components and features are typical in a machine vision system:

- Selected cameras in stainless steel enclosures

- Machine vision lighting in stainless steel enclosures

- Extruded aluminum or stainless steel mounting frame

- NEMA 4X control panel with embedded computer, HMI display and cooling (pictured)

- Ability to communicate with plant Windows network and PLC

Post-Commissioning Success

ProSensus’ clients are not required to have an in-depth understanding of a newly installed machine vision system. Rather, to ensure the accurate and reliable operation of this advanced equipment for a long life, ProSensus provides calibration SOPs and offers support and service contracts.

Additionally, ProSensus is available to provide analytics consulting services on the new source of data provided by a machine vision system. ProSensus is renowned for expertise in advanced analytics, and the data collected by a machine vision system can be highly valuable to process troubleshooting and product quality improvement.

Examples of our analytics services on this type of data include: summarizing key parameters in time-series, correlating quality metrics to process operations, and troubleshooting quality drifts.

On-Site Trial

Contact ProSensus today to get started with an on-site machine vision trial.